Southwest

Environmental Limited

Southwest

Environmental Limited Southwest

Environmental Limited

Southwest

Environmental Limited| London |

| 02076 920 670 |

| Exeter |

| 01392 927 961 |

| Manchester |

| 01612 970 026 |

| Bristol |

| 01173 270 092 |

An Interesting Fact about the paper Industry:

“The paper industry is

the 4th largest

contributor to greenhouse gas emissions among United States manufacturing

industries, and contributes 9%

of the manufacturing sector's carbon emissions”.

[xiv]

Now I know this relates to the USA but it gives a clue as to impact of paper production. So there is both a need for mitigation of this impact . . . . .and an opportunity to be made for the industry to cut emissions.

OOOOO is the UKs largest paper mill, and deals with mainly recycled fibres. The Company has ISO 14001, and has regular audits. But what could EPR do for this company?

A GOOD SET OF RULES TO FOLLOW:

If we look at the generic conditions specified in the permit[xvi] most of them are sensible things for a company to do, with the exception of companies like Shell it would seem that responsible behaviour is rewarded in the UK at least, and as such the generic conditions of EPR are good to follow.

Under 1.1 General Management we see;

“in accordance with a

written management system that identifies and minimises

risks of pollution, including those arising from

operations, maintenance, accidents,

incidents, non-conformances”

This is common sense stuff, ie if you are using diesel on site, you should have the means to mop it up if it spills on the ground, if the risk of such an occurrence is high, and likely to happen regularly then interceptor drains should be fitted. Since the Environment Act control of pollution has lent towards the punitive, now e are in the era of the preventative, better for the Environment, The companies image, insurance costs, and so on.

In 2.3 Operating techniques we see stipulations for safe operational techniques. Again advise on minimising environmental risk is beneficial, Environmental Liabilities are large and well worth avoiding.

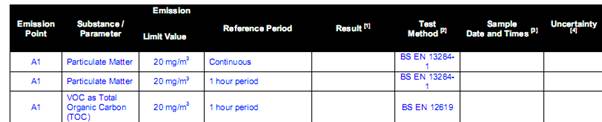

The Third Generic Condition is that of “Emissions and Monitoring”;

Emissions: “to air, water, or land” are set limits under the permit;

Any breach of these limits must be reported to the Environment Agency within a specified time frame (specified in the permit). Having an expert (perhaps) on the end of phone might be very useful if you are have a critical problem, the EA want to help, and this is a resource in itself.

Monitoring: emissions must be monitored, again knowing your emissions can be an important diagnostic tool in finding faults within your equipment, when a car fails it MOT on emissions it is because something has gone wrong with the engine / exhaust, when operating a paper mill worth £X Million, I am sure it would be good to know something was wrong before irreversible damage was caused.

Recording keeping is also stipulated under in the permit;

“at least 6 years from the date when the records

were made, or in the case of the following records until permit surrender:”

Good record keeping is essential in any business. It is beneficial for the following reasons;

a) If a pollution event occurs a long history of blemish free operation will help a company in its case. A company with regularly tarnished records however will have a negative experience in this instance.

b) Records of Emissions will be useful when assessing trends in use of fuel versus Sulphur Dioxide Emissions, if they are not proportionate is the quality of your fuel dropping? Etc

c) Publishing these records will help increase the “transparency” of your organisation and therefore share holder / customer perception of your brand.

The final Generic Condition sum up the rules expected to be adhered to by the operators, these are blanket expectations, if you are operating under a permit then, the guy down the road with a paper mill is having to work to the same standard, he cannot cut corners (environmentally) and undercut you, he will be in breach of his permit if he does, in this way EPR levels the playing field, and Industries that have been environmentally responsible can be assured that EPR levels the playing field to their competitors.

The generic template cited here, only gives a direction to follow, a real life permit has very specific targets to meet, and does and don’ts;

[xvii]

(couldn’t find completed permit

for paper and pulp sector)

[xvii]

(couldn’t find completed permit

for paper and pulp sector)

We can see from the stipulation in the above extract from a Viridor Permit (for a Hazardous Waste Site) that attention is given to the specifics of site operation. Detail of this nature can only be beneficial in the safe operation of a permitted activity.

BAT:

In order to be granted an environmental permit there must be some implementation of BAT, Generic BAT attributes are summarised below:

·

“Sufficient maintenance of the technical units and the

associated abatement techniques;

·

Environmental management system which optimises

management, increases awareness and includes goals and measures, process and job

instructions etc.

·

Training, education and motivation of staff and operators;

·

Process control optimisation;”[xviii]

This is familiar to EMS content, what details can be added?

[xix]

[xix]

The above diagram shows a simplified process tree for the manufacture of paper suitable for a low grade use such as newspaper, this diagram would become more complicated the higher the grade of the finished product..

Reading further on the the BAT Ref Document reveals steps that can be taken it improve efficiency:

“A systematic separation of the individual water

loops based on the counter current principle is essential.”

Further detail is given on the re- use of water;

“The possible rate of recycling depends on the

quality requirements of production and on the quality of the treated

process/wastewater. Besides, the quality of process design of the water circuits

strongly influences the limit of reuse without disadvantages for production and

product quality.”

Here we can see how EPR by enforcing BAT is making Manufacturers (or their consultants) look at detailed process, in this case technology to clean water for re-use, which they may be “forced in to” under EPR, they have been in fact been gifted a sound investment. By reusing water over the life of the plant their Operational Expenditure will be lower, in terms of water usage, perhaps energy.

[xx]

[xx]

Insight is also given in to chemical use, various chemical agents are used to improve the weight (density), workability and appearance of the paper, these are added to the pulp, practical advice is given on reducing environmental risk;

“Substances used for de-inking are shown in Table

5.7. De-inking chemicals have little retention to cellulose and can be expected

to be present in the de-inking sludge that is landfilled or incinerated.”

A company with lower environmental risk is;

After outlining the process we move on to the ASPECTS and IMPACTS associated with the processes;

Aspects are listed as such, it is useful to be provided with a list such as this, a plant operator / consultant / engineer can use it to focus on processes and try to mitigate against their damaging effects.

ASPECTS:

“-

Recovered paper consumption

-

Water use

-

Use of additives

-

Energy demand

-

Wastewater emissions

-

Solid waste generation from stock preparation, process

water clarification and wastewater treatment

-

Air emission from energy generation

-

Air emissions from sludge and residue incineration

(optional)

-

Noise from paper machines (local)

-

Odour from vapours and from wastewater treatment plant

(local)”

Each aspect is further elaborated upon, the BAT REF Document specifies areas of energy usage, in this case it highlights “Thickening and Disperging” as a major use of energy, so from viewing this we can deduct that that particular process might be a good place to design in efficiency.

If the mill was already up and running you might choose to prioritise the replacement of this equipment with more efficient alternatives.

IMPACTS:

An obvious impact to focus on is that of Energy Use, The efficient use of Energy is specifically highlighted in an EPR Permit Document and in BAT Ref, it also save the operator money! So all in all its a good place to start.

Above we see a table highlighting the various energy uses in preparation of the pulp before it enters the mill, as the pie chart of energy use highlight dispersing is an energy hungry process, and as we can see from the examples above the most efficient process minimises the amount of load on dispersing equipment by preparing the pulp more carefully before hand.

So whether a Paper Mill chooses the method in example one, or it is forced upon them by means of a BAT specification in there Permit Conditions they will, in the long term benefit from large energy savings.

“The driving forces to implement stock

preparation plant concepts with "minimised" process stages are lower investment

and operation costs mainly savings of electrical power as a result of the fewer

machines required”

SOME NEGATIVES?

A paper mill such as OOOOO, near OOOOO is typical of the run down state that we find British Industry. Investment is at a minimum. The factory labors on using equipment that in some cases in 100years old. Currently occupying a site a site which has a negative value in terms of possible contamination and decommissioning expenses, is there really a need to pile extra expenses on an ailing Industry, Yes; it reduces risks to the Environment, Yes; Investment may make for a more efficient process, but perhaps just as low income families pay less income tax, should low income industry be exempt from EPR regulations. Probably not, but a thought non the less.

But Does OOOOO Fall under 20 tones a day?

![]() [xxii]

[xxii]

A negative element of EPR and subsequent application of BAT may be the specification of a closed loop system for paper production which as the name suggest has zero discharge to the environment, this will have a negative effect on paper quality and cause equipment degradation;

“ inevitable accumulation of dissolved and

colloidal organic matter in closed water circuits creates severe problems as

corrosion, unpleasant odour in the paper produced and also in the vapour exhaust

of the paper machines.”

So in conclusion BAT pushes the less environmentally motivated, and pull the keen greenies in to a leaning greener, system of manufacture. In the past how would a company know which equipment would deliver the results they needed? They would have been at the mercy of a sales man, but now thanks to EPR and subsequently BAT there is a mass of information for people to access, in the Form of BAT Reference documents + Consultations with the EA, and if they are a bit lazy (Like OOOOO) Conditions attached to the approval of their permit.

[xv] OOOOO

[xvi]

[xviii] Reference Document on Best Available Techniques in the Pulp and Paper Industry (Chapter 5)

[xix] Reference Document on Best Available Techniques in the Pulp and Paper Industry (Chapter 5)

[xx] Reference Document on Best Available Techniques in the Pulp and Paper Industry (Chapter 5)

[xxi] Field Trip

[xxii] EPR 2010 CHAPTER 6 Other Activities SECTION 6.1